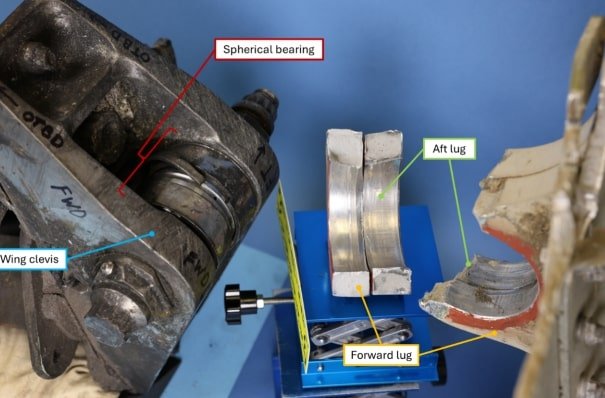

Louisville, United States: The National Transportation Safety Board (NTSB) said on Thursday its preliminary investigation into the Nov. 4 crash of UPS Flight 2976 in Louisville has identified fatigue cracks and areas of overstress failure on the left engine pylon aft mount lug, a structural connection that attaches the engine/pylon assembly to the wing. Investigators said the cracking preceded the accident and likely contributed to the pylon’s structural failure and subsequent separation of the left engine during takeoff.

The accident involved MD-11F freighter N259UP, operating a domestic UPS cargo flight from Louisville Muhammad Ali International Airport (SDF) to Honolulu, which was destroyed after impacting terrain shortly after liftoff. All three crewmembers aboard the aircraft and eleven people on the ground were fatally injured; 23 additional people on the ground were reported injured. The NTSB opened its investigation the day after the accident and recovered perishable data and wreckage for examination.

According to the preliminary report, investigators documented evidence of fatigue cracking in the left pylon aft mount lug and signs of overstress on adjacent structure. The report notes that when one side of the pylon support failed from fatigue cracking, the remaining structure could not carry the redistributed load and experienced overstress failure. Investigators are now focused on the component’s maintenance and inspection history to determine why the cracks were not detected.

NTSB officials said the discovery of fatigue cracks is a “major clue” in determining how the structural failure began but emphasized the investigation remains ongoing. The NTSB has invited parties including the FAA, UPS, Boeing (which acquired the MD-11 program after merging with McDonnell Douglas), GE Aerospace, and labor representatives to participate in the probe, and it will continue to collect and analyze flight data, maintenance records and metallurgical evidence. A final report is typically issued about a year after an accident.

The preliminary finding prompted immediate regulatory and industry responses. Boeing recommended that operators temporarily ground MD-11 aircraft pending further analysis; several carriers, including UPS and FedEx, temporarily removed MD-11s from service. The Federal Aviation Administration issued airworthiness directives that temporarily grounded the MD-11 and the related DC-10 model because of design commonalities affecting the pylon/wing attachment.

Local officials and first responders described a scene of intense destruction on impact. Video and photographic evidence included in the NTSB packet show the left engine separating from the aircraft and the airplane striking structures near the airport perimeter before being consumed by post-crash fire. Authorities closed portions of the airport in the immediate aftermath and emergency services responded to multiple ground casualties. Investigators said they will continue metallurgical analysis of the failed pylon components, review the aircraft’s full maintenance and repair history (including recent work performed by third-party repair facilities), and reconstruct load and stress conditions immediately prior to failure. The agency also is reviewing whether inspection protocols for that specific lug/component were adequate given the airplane’s age and usage cycles.