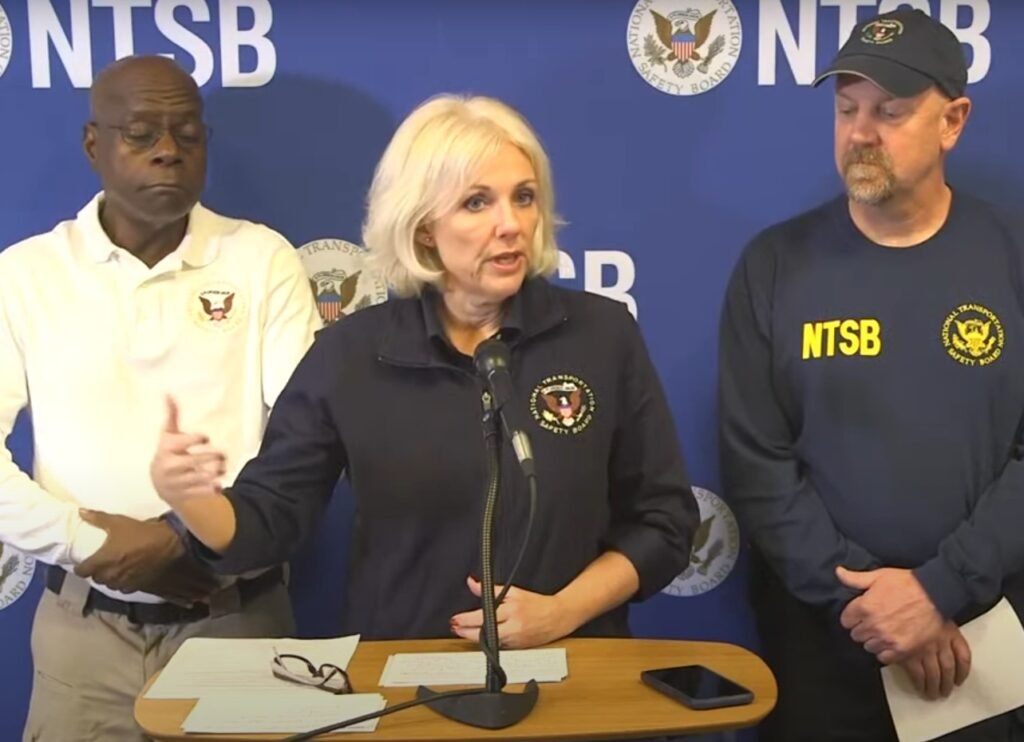

Washington, D.C., United States: The National Transportation Safety Board (NTSB) has released its final report into the in-flight depressurization incident involving Alaska Airlines Flight 1282, identifying critical failures by both Boeing and the Federal Aviation Administration (FAA). The incident, which occurred on January 5, 2024, involved the mid-cabin exit door plug separating mid-air from a Boeing 737-9 MAX, leading to an emergency landing in Portland, Oregon.

No fatalities occurred, though eight people sustained minor injuries. The NTSB investigation concludes that a series of manufacturing errors, documentation lapses, and oversight failures contributed to the serious safety breach.

Incident Summary

Alaska Airlines Flight 1282 departed from Portland International Airport at 5:07 p.m. on January 5, 2024. While climbing through approximately 14,830 feet, the aircraft experienced a sudden depressurization due to the separation of the left mid-cabin exit door plug. The cabin pressure rapidly dropped, oxygen masks deployed, and a loud explosive sound was heard.

The crew declared an emergency and landed safely back in Portland at 5:27 p.m., 20 minutes after departure. The aircraft was carrying 171 passengers and six crew members.

Manufacturing Lapses at Boeing Identified

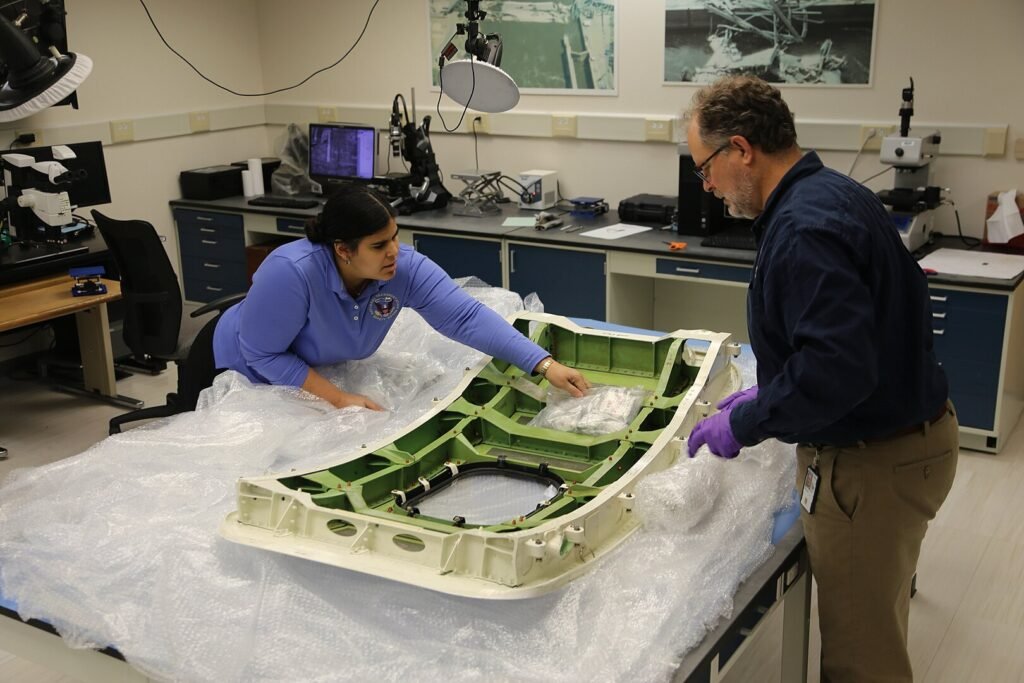

According to the NTSB’s 19-page final report, the door plug had been removed by Boeing personnel at the company’s Renton, Washington facility during fuselage repairs in September 2023. However, no documentation of the removal or reinstallation was found, violating standard production protocols. Furthermore, investigators determined that four critical bolts securing the door plug were never reinstalled.

Boeing’s internal tracking systems failed to log the maintenance action. The report states, “Boeing did not have procedures to ensure that the required safety documentation or final inspections were completed after door plug reinstallation.”

The door plug, which is used to cover an optional emergency exit area on high-density seating configurations, is designed to be held in place by 12 fittings and four key retention bolts. The NTSB confirmed that the plug gradually shifted out of position and ultimately detached due to missing fasteners.

Inadequate Training and Procedures

The NTSB noted that Boeing’s assembly teams lacked adequate training to properly handle door plug installations. The company’s work instructions were described as overly complex and lacking clarity, particularly regarding non-routine work.

The investigation found that the work was performed by a team unfamiliar with the procedure. It was further revealed that quality assurance staff failed to verify the bolt installation, allowing the aircraft to proceed through final assembly and delivery without detecting the omission.

FAA Oversight Deficiencies

In addition to Boeing’s errors, the NTSB cited the FAA’s ineffective compliance and surveillance mechanisms. While the agency had conducted multiple audits at Boeing facilities in prior years, it failed to detect or address systemic lapses in documentation, workforce training, and final assembly inspections.

The NTSB concluded that the FAA’s oversight was “inadequate to identify recurring noncompliance” and did not sufficiently mitigate risk associated with critical assembly processes.

Probable Cause and Contributing Factors

The report states the probable cause of the accident as:

“The in-flight separation of the left mid-cabin exit door plug due to the failure of Boeing to ensure that the plug was reinstalled with all required retention hardware during production… Contributing to the accident was the FAA’s ineffective oversight of Boeing’s production processes and safety compliance.”

Safety Recommendations Issued

In total, the NTSB issued 19 safety recommendations, including:

- A redesign of the 737-9 MAX mid-exit door plug to prevent inadvertent displacement

- Improved documentation protocols and quality control procedures for component removal and reinstallation

- Enhanced workforce training for Boeing production and quality assurance personnel

- Strengthened FAA audit procedures and risk-based surveillance methods

- Mandated tracking of critical fastener installation for all high-risk components

- Nine recommendations were directed to Boeing and ten to the FAA.

In a statement, Boeing acknowledged the findings and stated that it has implemented “significant corrective actions” in response to the incident and the investigation. The company has committed over $1 billion toward improving safety systems, production oversight, and employee training across its 737 program.

The FAA stated that it is reviewing the NTSB’s recommendations and has already implemented a production cap on 737 MAX aircraft pending further compliance improvements.

The January 2024 incident raised renewed scrutiny of the Boeing 737 MAX program, which had previously been grounded worldwide following two fatal crashes in 2018 and 2019. Following this event, hundreds of MAX 9 aircraft were temporarily grounded for inspection by the FAA, leading to widespread schedule disruptions for multiple airlines.